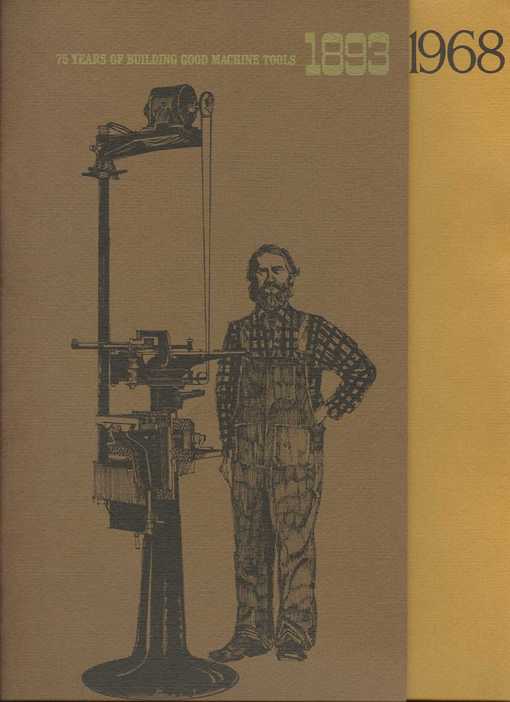

The George Gorton Machine Company

Founded in the Gorton family greenhouse in 1893, as Gorton and Graham Machine Co.,

it was a family owned business for roughly 75 years.

A variety of documents pertaining to the business of the company survive, and

many have been incorporated into this web site. There is also some content

related to various other business ventures undertaken by George II.

There are separate pages for:

In 1893, after getting forced out of

Racine Basket,

George II and Fred Graham (another former [Racine Basket] employee) formed

the Gorton and Graham Machine Co.

The company started with a debt of $1000 (a consequence of exiting Racine Basket);

their initial location was an unused greenhouse in the Gorton family backyard,

and was roughly 12' by 15'.

Another very early employee was Charlie Gorton, George II's younger brother.

However, without any noticable revenue, both Fred and Charlie

had to leave to take jobs which would actually pay;

in 1895, George II incorporated the George Gorton Machine Company.

For the first couple of years, the company designed and manufactured machines

related to basket making, and some wood slotting machines which were used in

the manufacture of window shades.

A variety of miscellaneous items were designed during this time period:

- collaborating on the design and construction of a prototype refrigeration unit

- a safer stove (fires started by stoves was apparently common)

- a safety can for gasoline (gasoline was used as a solvent and degreaser throughout

the machining industry) with featured a fusible link. If a fire started, the

lid would close, thus suffocating the fire

- an improved glue pot - staples, clips, and tape were either not yet invented, or

not available at that time, so glue was used. The improvement seems to have been to keep the glue from drying out as rapidly.

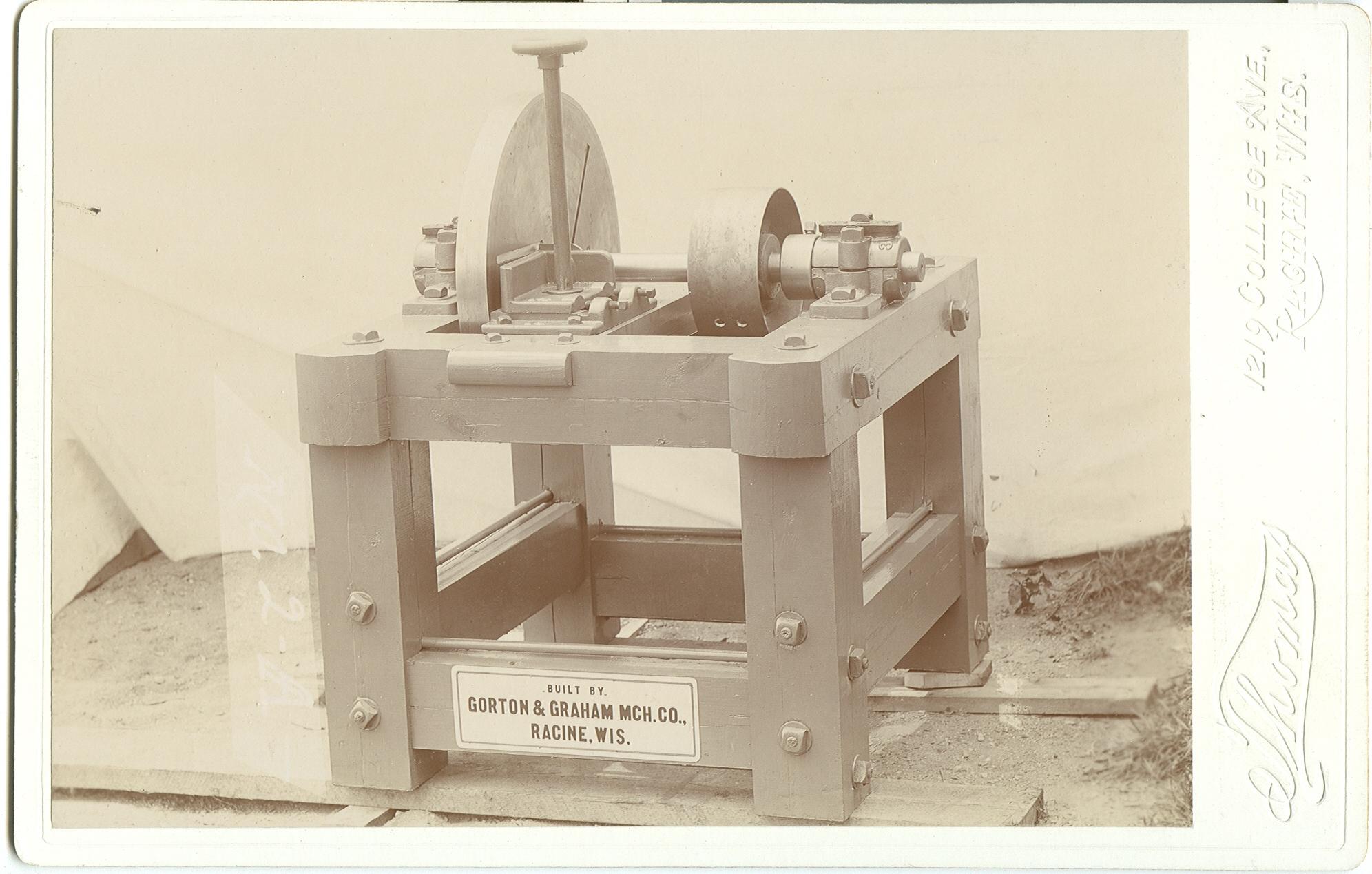

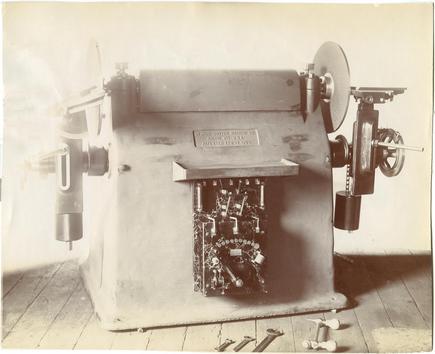

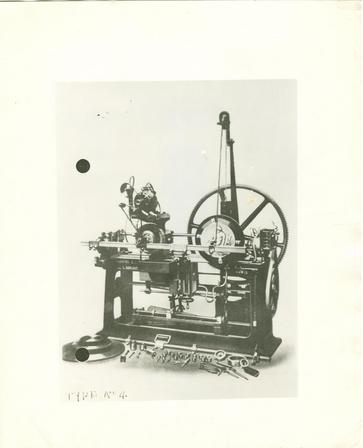

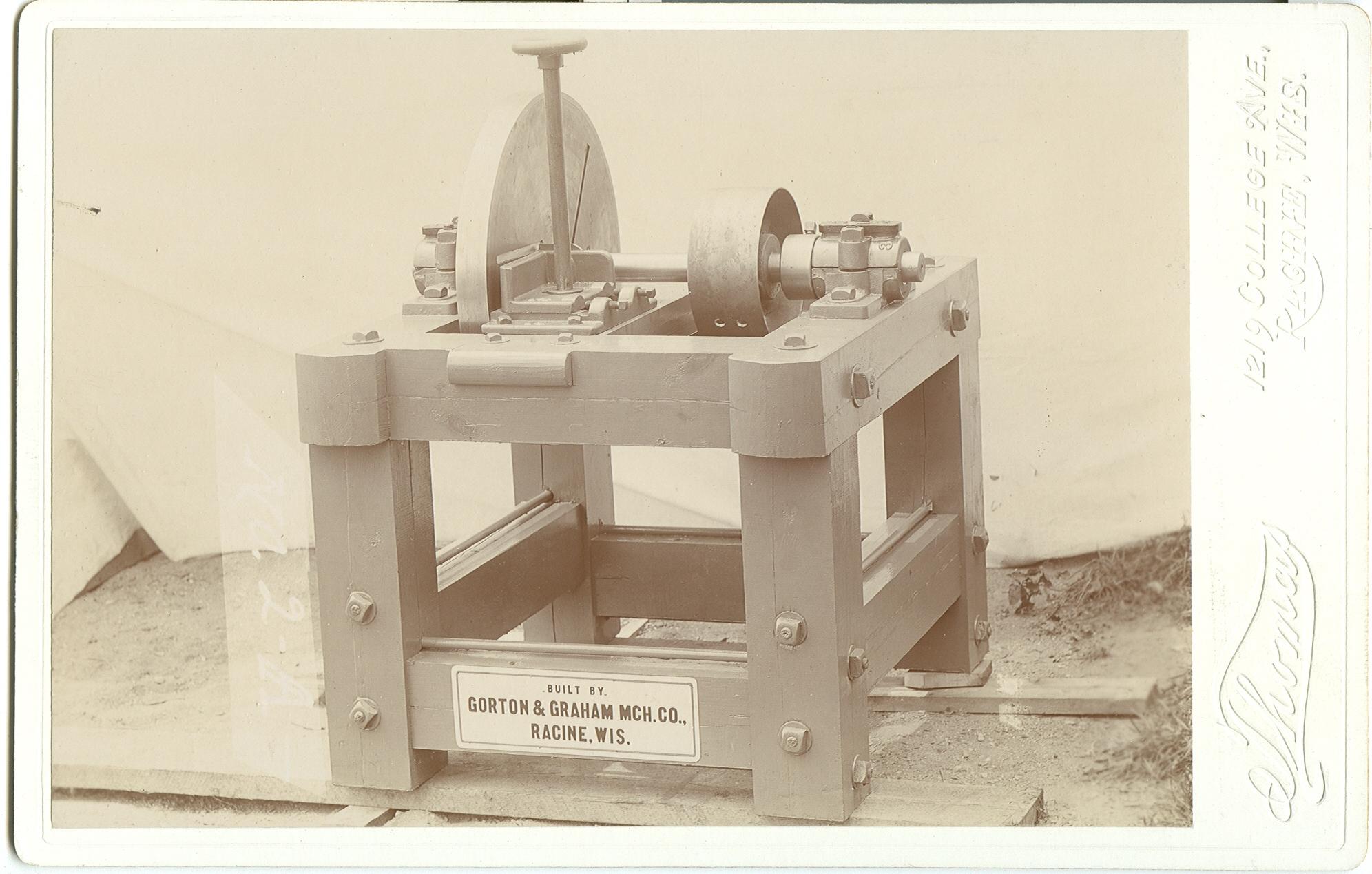

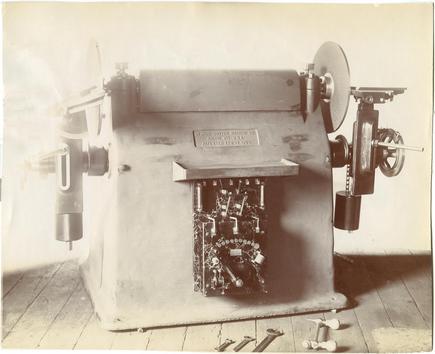

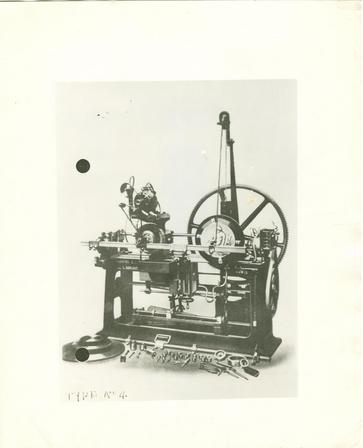

A pair of machines built under the Gorton and Graham name - the faint tags

say "No. 2-A" and "No. 3-A". Presumably the model types, rather than serial numbers.

Given when they were made, they may be for operations related to the manufacture of

baskets.

A series of photos (as well as a pair of 7x9 negatives) for a model

number 25 Gang Saw have also survived. Notes indicate this model was used

in barrel manufacturing.

A couple of product descriptions also survive (which confirm the suspicion about

the equipment being used in basket manufacturing):

The last one is an advertisement from 1898 about selling off the entire

basket manufacturing equipment line. To date, no details regarding the success

(or not) of this attempted sale have emerged.

Incorporated in 1895 as George Gorton Machine Co.

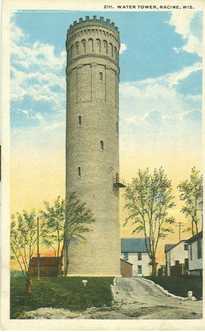

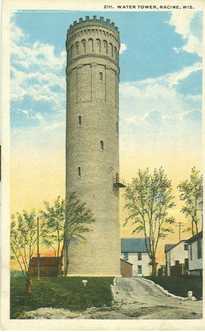

1897 - As a favor to Fred Graham, George designs a brick enclosure for the

330,000 gallon town water 'standpipe'. Fred submits the design, and wins

the building contract. This postcard (circa 1920s) is of a Racine water tower,

presumably the same (only?) one owned by the town. George's memoirs indicate

this tower is located just east of nortwestern rr, and north of 10th st.

One of the volunteers at the

Racine Heritage Museum

recalled this water tower from her childhood.

1898 - company enters into a (its first?) patent licensing

agreement. It is with

Taylor, Taylor & Hobson of Leicester, England for an engraving machine.

The company acquires US Patent rights to the design.

1898 - company enters into a (its first?) patent licensing

agreement. It is with

Taylor, Taylor & Hobson of Leicester, England for an engraving machine.

The company acquires US Patent rights to the design.

An improved version of the pantograph, the 1-A is built; the first one is sold

to Western Electric of Chicagor for about $325.00.

1899- A second pantograph is sold to C.P. Goerz, an optical company, in New York City.

1899 - The company starts advertising disc grinders in the machinery trade press.

Late 1890's - George II designs a safer coal-burning stove (for heating)

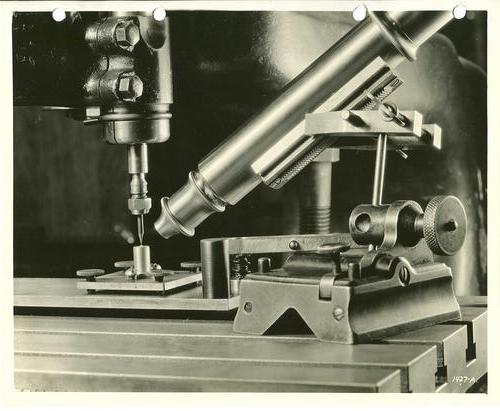

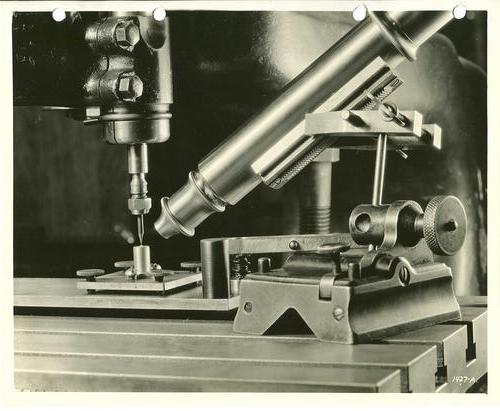

Given the sequence number, this photo was taken after the end of WWII.

This may be the very one mentioned by George II in his memoirs.

April, 1900 - Paris Industrial Exposition held; Gorton Machine earns

a bronze for excellence in design of disc grinding equipment. Presumably, this

scrap of paper relates to the medal and award.

April, 1900 - Paris Industrial Exposition held; Gorton Machine earns

a bronze for excellence in design of disc grinding equipment. Presumably, this

scrap of paper relates to the medal and award.

1900 - First product catalog (all grinding machines) of 40 pages published

1900 - Company wins "Highest Award" at the Paris Exposition, 1900.

The medal is recreated

here in print. The original

medal itself is likely long since lost.

Some photos of early grinders (note the 'patented 1903' stamp) many of which

are from a catalog George II assembled for,

and in honor of the birth of his first child, George III. The (oversize) catalog

is dated Oct. 27, 1903, and is mounted on very heavy cardstock. Discolorations

visible are actual, and from the leaching of the items on the opposite pages

where it occurs. The small screw presses adjacent to the machines in a couple

of the photos are for adhering the abrasive surface to the metal backing disc.

From various patents, it does appear that the abrasive surfaces were paper or

cloth discs that are then glued to the metal. Also of note is the availability

of the products with either built-in electric motors or overhead pulley systems

to provide the power. The last photo in this series is also identified (by other

photos) as Form #70 in the

form index.

1900 - First product catalog (all grinding machines) of 40 pages published

1900 - Company wins "Highest Award" at the Paris Exposition, 1900.

The medal is recreated

here in print. The original

medal itself is likely long since lost.

Some photos of early grinders (note the 'patented 1903' stamp) many of which

are from a catalog George II assembled for,

and in honor of the birth of his first child, George III. The (oversize) catalog

is dated Oct. 27, 1903, and is mounted on very heavy cardstock. Discolorations

visible are actual, and from the leaching of the items on the opposite pages

where it occurs. The small screw presses adjacent to the machines in a couple

of the photos are for adhering the abrasive surface to the metal backing disc.

From various patents, it does appear that the abrasive surfaces were paper or

cloth discs that are then glued to the metal. Also of note is the availability

of the products with either built-in electric motors or overhead pulley systems

to provide the power. The last photo in this series is also identified (by other

photos) as Form #70 in the

form index.

A surviving Model #3 grinder, put up on http://www.ebay.com for sale in

December, 2006 (making it more than 100 years old!) Clearly, it has been

modernized to use a current electric motor, but it is still an impressive feat

for machine tool to still be in use after 100 years.

A surviving Model #3 grinder, put up on http://www.ebay.com for sale in

December, 2006 (making it more than 100 years old!) Clearly, it has been

modernized to use a current electric motor, but it is still an impressive feat

for machine tool to still be in use after 100 years.

1903 - George informed that he has 6 months to live due to an extremely bad

kidney infection. A complete change in diet helps, and he recovers in roughly

a year.

1903 - while ill, George II decides to sell the Disc grinder business; it

is purchased by the Diamond Machine Company of Providence, RI.

A whitepaper about the company's expertise

in the business of abrasives and grinding has survived. In the archival material,

there are two copies of the second page, and the last page is clearly missing.

An early pantograph built by Janvier & Berchot (Paris). Presumably

in the company files as a reference point about different types of pantographs

1903 - George informed that he has 6 months to live due to an extremely bad

kidney infection. A complete change in diet helps, and he recovers in roughly

a year.

1903 - while ill, George II decides to sell the Disc grinder business; it

is purchased by the Diamond Machine Company of Providence, RI.

A whitepaper about the company's expertise

in the business of abrasives and grinding has survived. In the archival material,

there are two copies of the second page, and the last page is clearly missing.

An early pantograph built by Janvier & Berchot (Paris). Presumably

in the company files as a reference point about different types of pantographs

about 1909 - Model 1-D, 1-G, 1-J and finally 1-S pantographs designed and built

June, 1910 - a document

(titled "PRELIMINARY INFORMATION") is written to facilitate the sale of the disc grinder

patents.

about 1909 - Model 1-D, 1-G, 1-J and finally 1-S pantographs designed and built

June, 1910 - a document

(titled "PRELIMINARY INFORMATION") is written to facilitate the sale of the disc grinder

patents.

It is 18 pages long, and was both glued across the top, as well as fastened with

a circular rivet-like insert.

It is unknown (at least to this author) how successful

said effort was.

1908 - 1912 - George designs (and improves upon) internal toothed cutoff

machines. The big advantage is the rate of speed at which they can cut stock.

During WWI, the company sells a large number of cutoff machines.

Photos of some of these at customer sites.

1908 - 1912 - George designs (and improves upon) internal toothed cutoff

machines. The big advantage is the rate of speed at which they can cut stock.

During WWI, the company sells a large number of cutoff machines.

Photos of some of these at customer sites.

1909 -Gorton Gate and Fence Company of Waukegan, Ill. started.

1909 -Gorton Gate and Fence Company of Waukegan, Ill. started.

As part of this, worked with George Tausch of the Cyclone Fence Company;

designed a machine to 'weave' cyclone fences. Multiple patents assigned to

George as a result of this business.

1916 - The Sept 1, 1916 issue of "Machinery" magazine runs a short article

about the company entitled "The Unknown Plant". The article has been cut out, and

glued to the front of a company envelope, along with a note by George II saying:

"Thanks Dear Machinery - Come around again in 90 days"

1916 - A Racine area book is published with about two pages of biographical

information about prominent locals. George II is in it, and given the level

of detail about the Gorton Machine cutting-off machinery, it was written by

him, or with a lot of input from him. A company description (in volume 1 of

the same book) indicates that at that time, the company employed about 50 men;

was made into a corporation in 1895; officers of the company are George, president

and treasurer; and S. Gorton (Sophy), vice-president.

(prior to July, 1917) The company initiates

legal proceedings vs. Peter Grignon, doing business

as Marine Iron & Shipbuilding works; the litigation makes it to the Minnesota State

Supreme Court. It is reported by the Northwestern Reporter (digitized by Google).

1917-1918 - George & Sophy, active in the First Baptist Church

of Racine, decide to donate a building to their church out of the profits from

building war machinery (presumably fuse routers, possibly cutoff machines).

The initial donation is $50,000, but (based upon information in George III's book

'A "Big-Ass Boy" In the Oil Fields') this was overrun by another $86,000; George

and Sophy 'cheerfully' covered this. The building was capable of seating 500,

had a gymnasium, two bowling alleys, a ladies parlor, and a gentlemen's lounging

room. The church named it 'Gorton Hall'; it still exists as of 2006.

In the 1921 "R.G.Dun Mercantile Agency Reference Book", the company is

rated as "B 1", meaning estimated value $200K - $300K, High Credit rating.

1917-1927: George & family spend much of their time living in Oklahoma,

with some time in Racine. Company mostly being run by ???. According to

George III's book, at one point a representative from Shell Oil offered

George II $1Million to buy his oil rights and property. George II turned

this down, believing that the rights were worth more. Based upon George II's

memoirs, the whole adventure in Oklahoma was a financial disaster.

The Gorton Trust

was the business trust to prospect for oil and gas.

1916 - A Racine area book is published with about two pages of biographical

information about prominent locals. George II is in it, and given the level

of detail about the Gorton Machine cutting-off machinery, it was written by

him, or with a lot of input from him. A company description (in volume 1 of

the same book) indicates that at that time, the company employed about 50 men;

was made into a corporation in 1895; officers of the company are George, president

and treasurer; and S. Gorton (Sophy), vice-president.

(prior to July, 1917) The company initiates

legal proceedings vs. Peter Grignon, doing business

as Marine Iron & Shipbuilding works; the litigation makes it to the Minnesota State

Supreme Court. It is reported by the Northwestern Reporter (digitized by Google).

1917-1918 - George & Sophy, active in the First Baptist Church

of Racine, decide to donate a building to their church out of the profits from

building war machinery (presumably fuse routers, possibly cutoff machines).

The initial donation is $50,000, but (based upon information in George III's book

'A "Big-Ass Boy" In the Oil Fields') this was overrun by another $86,000; George

and Sophy 'cheerfully' covered this. The building was capable of seating 500,

had a gymnasium, two bowling alleys, a ladies parlor, and a gentlemen's lounging

room. The church named it 'Gorton Hall'; it still exists as of 2006.

In the 1921 "R.G.Dun Mercantile Agency Reference Book", the company is

rated as "B 1", meaning estimated value $200K - $300K, High Credit rating.

1917-1927: George & family spend much of their time living in Oklahoma,

with some time in Racine. Company mostly being run by ???. According to

George III's book, at one point a representative from Shell Oil offered

George II $1Million to buy his oil rights and property. George II turned

this down, believing that the rights were worth more. Based upon George II's

memoirs, the whole adventure in Oklahoma was a financial disaster.

The Gorton Trust

was the business trust to prospect for oil and gas.

1934 - start of the effort to engrage the Lord's prayer on the point of a pin

1934 - start of the effort to engrage the Lord's prayer on the point of a pin

The company was looking for a showcase piece of work to display at the 1935

National Machine Tool Builders Association (which would be held in Cleveland).

It would be the first time the company exhibited at the show, and George II wanted

"to make a lasting impression on as many visitors as possible."

As a demonstration of the quality and precision of the companies pantographs,

the company undertook the effort to engrave the Lord's Prayer [King James Bible,

Matthew 6:9-13] in as small an area as possible. The initial effort was

engraved in a 1/32nd" circle, but the final result was within a circle of .005"

diameter, the size of a point of a pin, or about twice the diameter of a human

hair.

To put this in perspective, the letters in the engraving are 1/40,000 of an

inch deep (depth cut into the wire), and 1/10,000 of an inch tall.

In meters: 64nm tall, and 258nm (.25micron) deep. Microprocessors shrank to .25

microns in the late 1990s, more than 60 years after the feat was

achieved through purely mechanical means.

A bit more detail is

here.

An

article from the Oct. 28, 1935 Journal Times about how the company

"helped to banish [the] depression". At that point in time, about 85 were

employed; at the worst point of the depression (1932 for machine tool builders)

the company employed about 15. A number of employees were interviewed for the

article, and photos and approximate length of service are given for each.

The employees include:

-

George Horner, 1133 Arthur Ave. In charge of the engraving department,

about 25 years of service (at which time about a dozen were employed.

-

Fred Kobal, 2434 E. Twentieth St. lathe operator, joined the company in 1915

-

Oscar Triebel, 3316 Second Ave, foreman of shipping,

joined the company in 1927.

-

John Burant, 1625 Morton Ave, machinist, joined the company in 1918.

-

Augie Jensen, Rt. 3, Box 162, machinist, joined the company in 1927.

-

Victor Heck, 1632 Grange Ave, assembler, engraving machines,

joined the company in 1911.

-

Frank Davis, 1540 South Main St., 26 years of service (joined in 1909).

-

Robert Lunn, 3615 Lindermann Ave., 2 years of service (joined in 1933).

-

Frank Klema, 2055 LaSalle st. machinist, 22 years of service

(joined in 1913)

-

Otto Schiess, 1102 Prospect St., machinist, 8 years of service

(joined in 1913)

-

Ernest Falkenrath, 1428 Franklin St. joined the company in 1901, and is

the oldest employee in "point of service" (years of service)

The article has been scanned as 5 separate images:

Nov, 1937 - grand opening of an employee

recreation hall.

Photos of the employees and facilities. On the assumption that these were all

taken on the same day (because the sequence numbers are all "1485"), and because

the company seems to have been quite good about making the sequence numbers ascending

and corresponding to chronological order, I believe these were all taken on

Wednesday, 16 February, 1938. Additionally, because we know the time at which

the first photo was taken (3:50pm) it is probably possible to determine which

way is North (but that would require additional evaluation of shadows...)

The woman in photo 2 may be related to the man in photo 3.

Lastly, it is worth looking very closely at the bowling team. The shirts appear

to be very nice, and somewhat reflective (silk?) All the shirts (excepting for

the two fellows front row left end) are monogrammed as well.

In any case, here are a series of photos of the facilities.

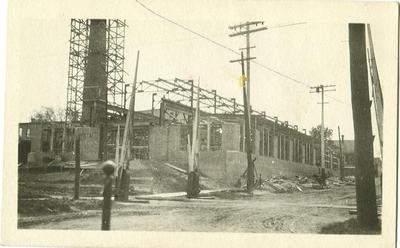

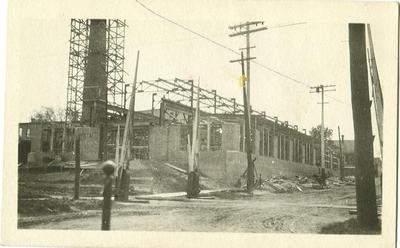

Sometime prior to 1940: the company expands its facilities

Sometime prior to 1940: the company expands its facilities

A book (about 4 inches thick of various forms: 15xx and 16xx) of various photos

of forms 15xx and 16xx. Late 1930s to early 1940s.

A book (about 4 inches thick of various forms: 15xx and 16xx) of various photos

of forms 15xx and 16xx. Late 1930s to early 1940s.

Presumably posing for camera, while "discussing" bases for mills. Probably the

set of individuals customers would most likely to have contact with. Everyone is

arranged far too carefully in a nice photogenic manner for this to be

by coincidence. Probably 1939, or early 1940. Alternative copy of a photo found in

the book of

<15xx and 16xx photos>. From left to right:

Peter Henkes, Charles Gorton, George Gorton II, James Gorton (standing), George Gorton III,

Ted Dumond. Labeled in the photo in the book.

Presumably posing for camera, while "discussing" bases for mills. Probably the

set of individuals customers would most likely to have contact with. Everyone is

arranged far too carefully in a nice photogenic manner for this to be

by coincidence. Probably 1939, or early 1940. Alternative copy of a photo found in

the book of

<15xx and 16xx photos>. From left to right:

Peter Henkes, Charles Gorton, George Gorton II, James Gorton (standing), George Gorton III,

Ted Dumond. Labeled in the photo in the book.

Feb, 1940 - George II turns 75. A big party thrown for him by the employees.

Photos of that event, along with other company specific photos are

here.

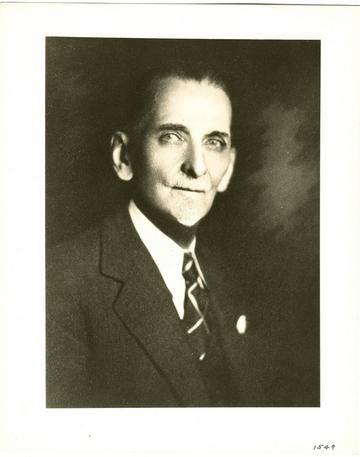

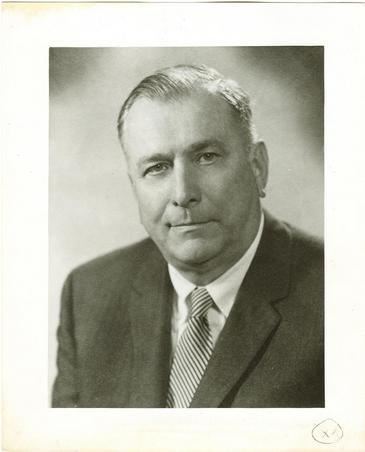

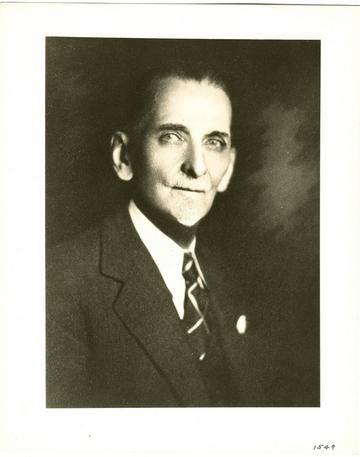

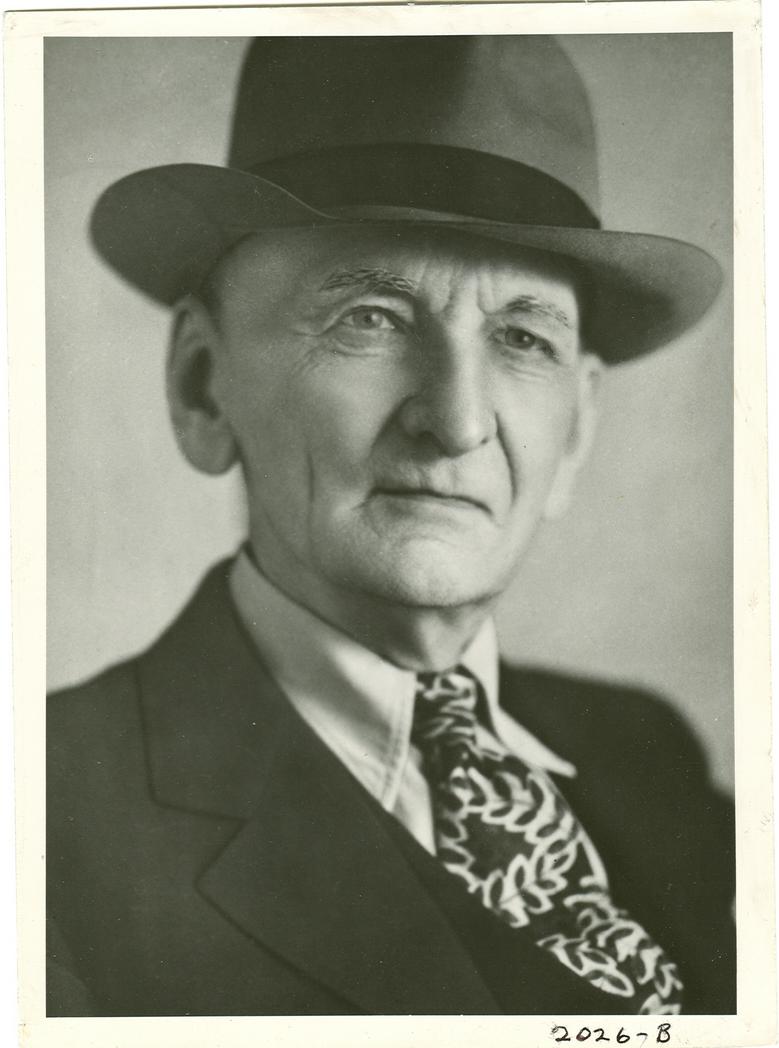

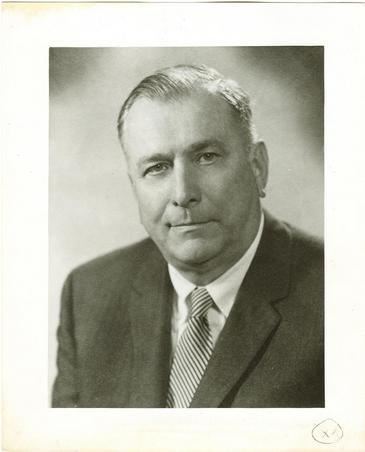

Corporate photo of George II, date unknown, but approximately 1940-1942.

Feb, 1940 - George II turns 75. A big party thrown for him by the employees.

Photos of that event, along with other company specific photos are

here.

Corporate photo of George II, date unknown, but approximately 1940-1942.

An article in the Racine Journal Times, May 31, 1940. The article is a general

description of the company's products and some of their uses. One claim of note

is that the companies' machines [presumably pantographs] have been used to make

money for the US, Norwegian, and Canadian governments.

An article in the Racine Journal Times, May 31, 1940. The article is a general

description of the company's products and some of their uses. One claim of note

is that the companies' machines [presumably pantographs] have been used to make

money for the US, Norwegian, and Canadian governments.

13 Sept. 1941 - Racine Journal Times article

Gorton machine tools have been pladced on "America's priority list, to be sold only

to those most urgently in need." Gorton Duplicators are used all over the nation in

duplicating dies, models, and various intricate parts used in aircraft, ships,

guns, and tanks. Even when running at 118 hours a week, the plant is unable to

keep up with the demand. Gorton machines are used to manufacture such precision

parts as the Norden bombsight, supercharger components, engraved scales (such as

those on rifle sights).

Date unknown, but presumably during WWII: Gorton Machine starts producing a

combination tool room machine for "Russian Tow Boats". Why a "Tow Boat"

needs machine tools is unclear. How and why Gorton picked this line up

from Gilman is unknown.

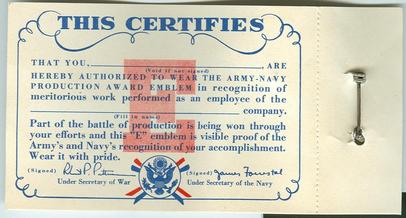

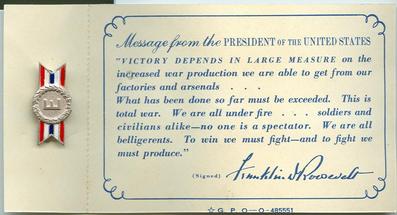

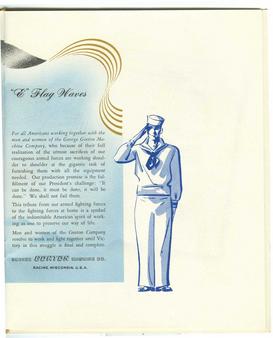

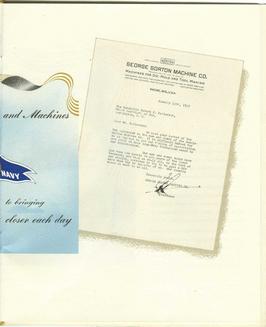

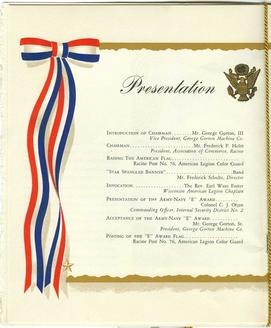

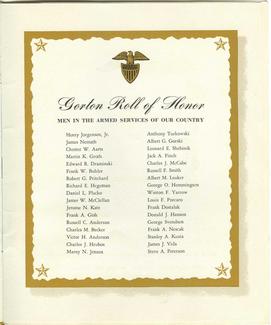

Awarded the Army Navy "E" award on Feb. 6, 1943

Awarded the Army Navy "E" award on Feb. 6, 1943

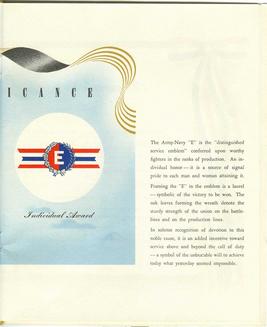

The "E" award was given out on a per-plant (rather than

per-company) basis for production excellence during the war.

It was not an easily obtained award, and George II was very proud

of the fact that his employees earned the award. It was the

first

Army Navy "E" award given to a plant in Racine. The efforts of

the employees resulted in the company earning an additional 4 stars

to the award.

There are a number of artifacts pertaining to the award:

A Racine Journal Times article from

13 June, 1944 indicates that the company was the first (multiple times) in Racine

to win production awards: the first "E" award, the first to win a white star,

the first to win a second white star.

Family oral history about the "E" award ceremony (Dave Rowland) - as a boy,

Dave attended the ceremony with his grandfather. When George II was spotted

nearby, one of his employees yelled "There's the Old Man!" and a great

cheer from the rest of the employees went up.

August 29 - 300 workers walk out (a huge percentage) due to an extension of work

hours to try to catch up on war orders. The Milwaukee Sentinel reports that some

300 workers were in a work stoppage - the company had "arranged overlapping

schedules in order to catch up on war orders". Whatever that means.

September, 1944 Machinery magazine gives a Distinguished Service award to George II.

This is the negative.

Jan. 9, 1945 - War production rally photos

Jan. 9, 1945 - War production rally photos

Feb, 1945 - George II turns 80. The employees in the shop

write a poem for him to honor the event

Oral history: (date unknown) from Dave Rowland. Possibly an urban legend (Dave

was skeptical about the validity of the story, but retold it as he had heard it):

A worker rushed into George's office and exclaimed "Mr. Gorton Mr. Gorton - there's

been an accident" to which George inquired as to where, and asked to be taken there.

Upon arrival, it was discovered that an employee had lost a finger (specifics

not given) to some accident in the factory. George asked how it happened, so

the employee obliged in a highly accurate recreation, but with a different finger,

and thus lost a second finger.

Feb, 1945 - George II turns 80. The employees in the shop

write a poem for him to honor the event

Oral history: (date unknown) from Dave Rowland. Possibly an urban legend (Dave

was skeptical about the validity of the story, but retold it as he had heard it):

A worker rushed into George's office and exclaimed "Mr. Gorton Mr. Gorton - there's

been an accident" to which George inquired as to where, and asked to be taken there.

Upon arrival, it was discovered that an employee had lost a finger (specifics

not given) to some accident in the factory. George asked how it happened, so

the employee obliged in a highly accurate recreation, but with a different finger,

and thus lost a second finger.

Further details (John Gorton) - John recalls the story as well, and that it happened

in the pattern shop.

It may actually be true, given that specifics of who and a location appear in the

story; secondly, the timeframe pre-dates OSHA by at least 20 years. OSHA was

created in 1974; George II died in 1955, and was likely not active in the company

on a day-to-day basis for some number of years prior to his death at age 90.

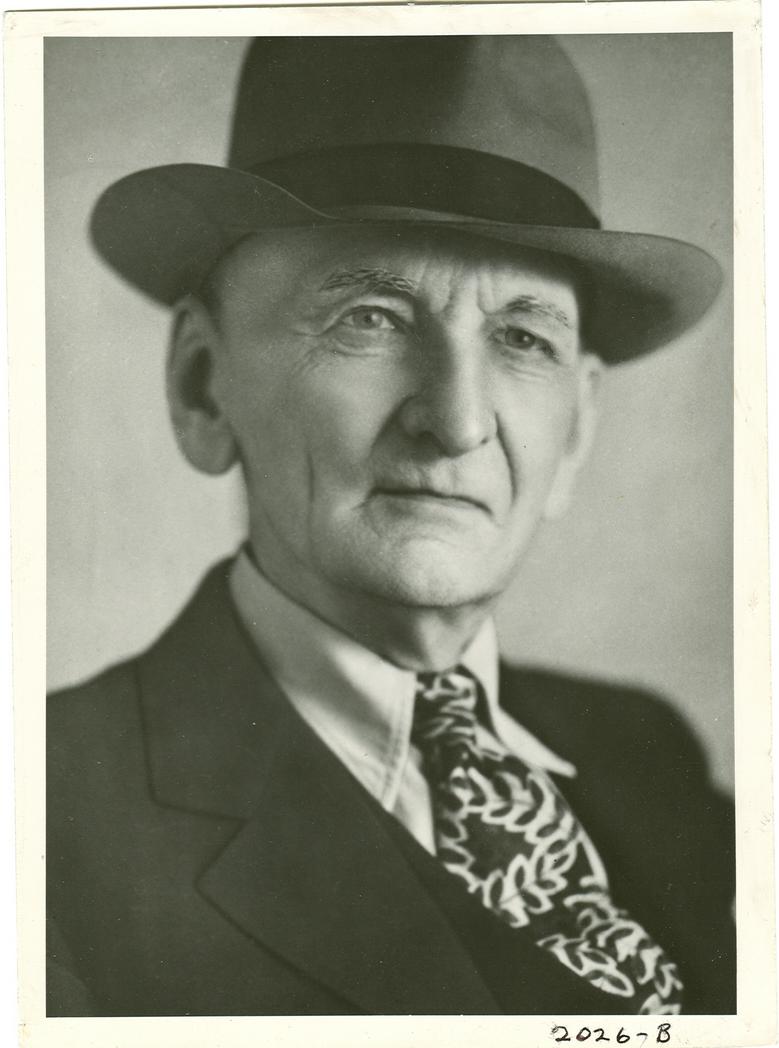

Official company photos of Charles and George II. Both are from formal portraits:

Charles' is

this

one, only in a smaller form factor (the large one got a little bit truncated at

scan time). The formal portrait of George used is

here.

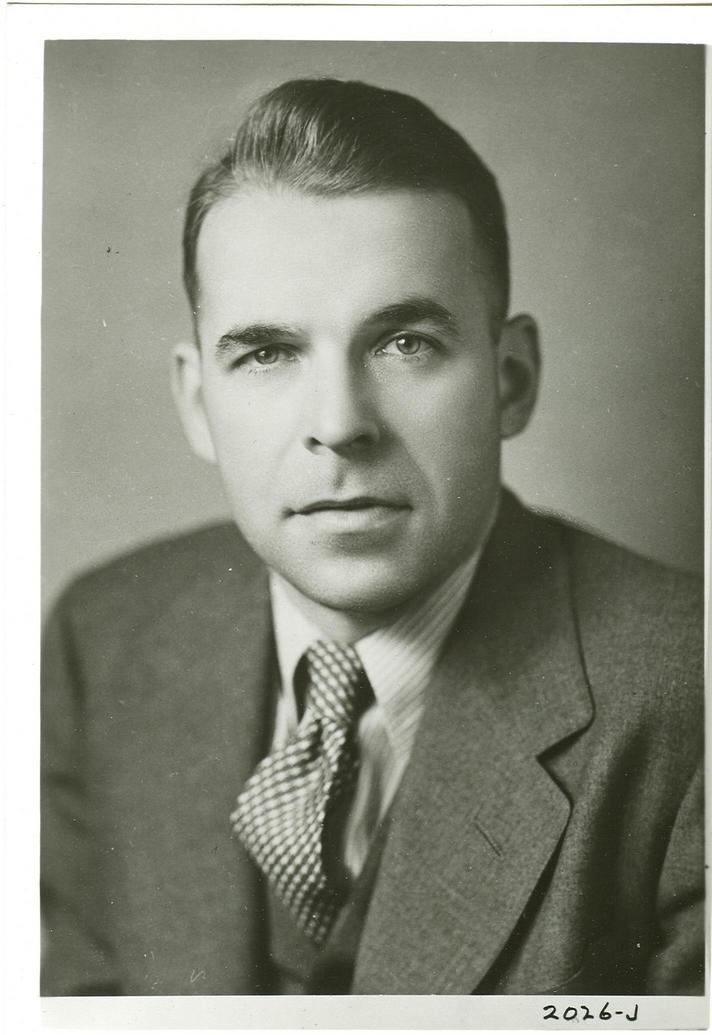

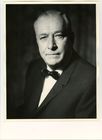

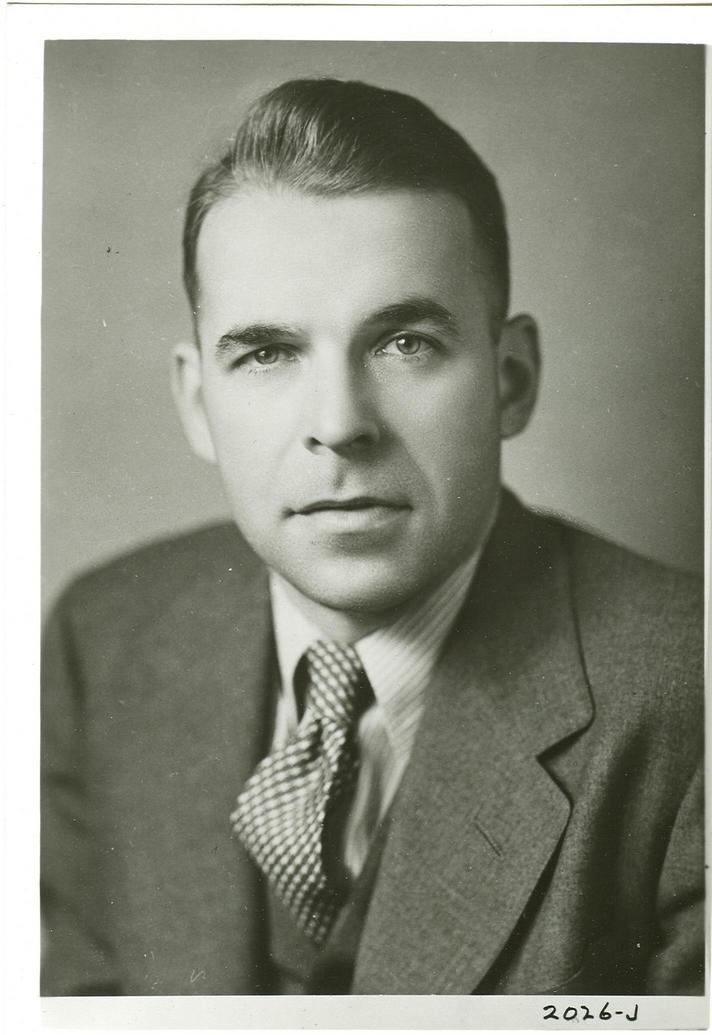

Three un-numbered photos of George III; he is a few years younger in the photo

on the right

Three un-numbered photos of George III; he is a few years younger in the photo

on the right

Gormac Products, Inc. spun off as a machine tool job shop

1947 National Machine Tool Show (in Chicago)

Gormac Products, Inc. spun off as a machine tool job shop

1947 National Machine Tool Show (in Chicago)

Feb, 1949 - The Labor Relations Institute of New York (a nationwide organization

at that time) presented its first annual national labor relations Award to the

company for recognizing that workers have an equity in the factory. The institute

represents more than 7,000 businesses. Various company and union officials

expressed their belief that it took a significant co-operative effort all

down the production line to earn the citation.

1952 - The company leases a

former (WW II) Hemp mill in Union Grove; the

building will house "Department 50", employing 50-60 people, and

produce milling machines.

Feb 5, 1955 - George II turns 90. And

goes to work!

Here are a series of

photos taken that day. And, as usual, he is wearing his Army/Navy "E" production

award pin.

Feb, 1949 - The Labor Relations Institute of New York (a nationwide organization

at that time) presented its first annual national labor relations Award to the

company for recognizing that workers have an equity in the factory. The institute

represents more than 7,000 businesses. Various company and union officials

expressed their belief that it took a significant co-operative effort all

down the production line to earn the citation.

1952 - The company leases a

former (WW II) Hemp mill in Union Grove; the

building will house "Department 50", employing 50-60 people, and

produce milling machines.

Feb 5, 1955 - George II turns 90. And

goes to work!

Here are a series of

photos taken that day. And, as usual, he is wearing his Army/Navy "E" production

award pin.

Nov. 22, 1955 - George II dies, aged 90.

The National Machine Tool Builders Association issued this

memorial of achievement

in 1956.

Nov - early Dec, 1955

Nov. 22, 1955 - George II dies, aged 90.

The National Machine Tool Builders Association issued this

memorial of achievement

in 1956.

Nov - early Dec, 1955

George III is elected president of the company; other officers and directors

of the company are:

Charles Gorton, VP of manufacturing, director

James Gorton (San Marino, CA), VP of research and development, director

Walter B. Tomlinson, VP and treasurer, director

Howard C. Holmdohl, secretary

John Elholm Jr., assistant secretary

Kenneth N. Findley (Milwaukee), director

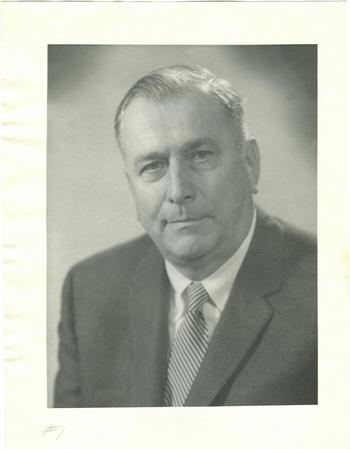

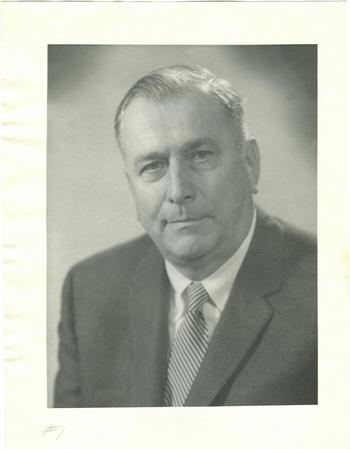

A company photo of Charles, George III, and James. Probably from the 1950s, or

early 1960s (James died in 1962).

14 Oct. 1962 - Racine Journal Times article:

The company sets up a department to rebuild old or damaged Gorton machines.

The machine tool industry is described as having an increased demand to have

machines overhauled by the original manufacturer.

Some photos from a dinner, probably a board of directors meeting. Again, late

1950s or early 1960s. Individuals in photo 1 (from left to right):

Standing: unknown, George Gorton III, unknown, James Gorton, unknown, unknown,

unknown, unknown, Charles Gorton.

Seated: unknown, Ken Findley, unknown.

A pair of publicity photos of George Gorton III. Date unknown.

The back says "Please Credit Blackstone-Shelburne NY"

A pair of publicity photos of George Gorton III. Date unknown.

The back says "Please Credit Blackstone-Shelburne NY"

The company creates a (pair of?) very high precision lathe(s)

What makes this/these machines so fascinating is the combination of when it was

created, the machine requirements, and the entity they were created for.

The machine was delivered in 1964. The requirements were that the machine be

extremely precise: 5 microns spindle runout, which is still non-trivial for

mechanical machines. Test machining on mild steel was required.

(Remember that this is before the advent of broadly available computer systems)

The customer was Union Carbide Nuclear Company, of Oak Ridge Tennessee.

General Electric (GE) was somehow involved in the ordering chain, but

the business details are unclear.

Some oral history/anecdotes: Family recollections indicate this machine was

destined for Hanford, Washington, and one of the key items is that it was

designed to be remotely operated, once installed. Specifically, tele-operated.

At a guess, this/these machines were designed to machine plutonium devices.

They were hydraulically driven with remote controls, which makes them less

susceptible to the effects of radiation on electrical/electronic systems.

Plutonium is inferred, as there is no real need to perform precision machining

on Uranium for reactor systems. And the non-military needs of such a high

precision at Oak Ridge are minimal. But the precision further implies facts

about plutonium based devices, namely that a maximal, close-fitting surface area

is desirable. Furthermore, the published machining characteristics of

plutonium approximate mild steel.

A newspaper article in the Racine Journal Times

from 1960.

It describes a series of company machines organized into a completely automated assembly

line to manufacture M-14 rifle receivers for the U.S. Army Ordnance Springfield Armory,

in Springfield, MA.

Renamed Gorton Machine Corp. around 1967

April, 1967 - the company sold to Kearney & Trecker

Renamed Gorton Machine Corp. around 1967

April, 1967 - the company sold to Kearney & Trecker

A newspaper article (probably the Racine Journal Times) indicates the company

was an all-stock transaction of 115,000 shares of Kearney & Trecker stock,

valued at $7.1 Million. At that point in time, the company employed 325 people

at two plants at 1321 Racine. St. and that an expansion announcement might be

made shortly.

1 July 1967 - Racine Journal Times article:

On June 30, the board of directors decided to purchase a 62 acre site on

Highway 11. The construction contract will go to Johnson & Hendrickson

Contractors (of Racine).

24 July, 1967 - groundbreaking at the new factory on Highway 11

Attendees include (then) Gov. Warren Knowles, George Gorton III, and Francis

Trecker. The 62-acre site will house an initial 135,000 sq. ft factory, with an

accompanying office building to be erected later.

The Racine Journal Times article has some interesting content: The new facility

will enable the company to build three new, significantly larger, machine tools,

and that these new tools are expected to add $5 to $8 Million in annual production

volume.

Attendees include (then) Gov. Warren Knowles, George Gorton III, and Francis

Trecker. The 62-acre site will house an initial 135,000 sq. ft factory, with an

accompanying office building to be erected later.

The Racine Journal Times article has some interesting content: The new facility

will enable the company to build three new, significantly larger, machine tools,

and that these new tools are expected to add $5 to $8 Million in annual production

volume.

[Authors note:] I remember watching my great uncle George (George III) using

a [ceremonial] silver shovel to dig the first shovelful, and wondering aloud to

my father what was the big deal? After all, at age almost-6, playing with dirt

and sand with a shovel was still fun; but not something normally done by

grownups.

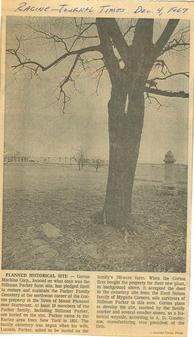

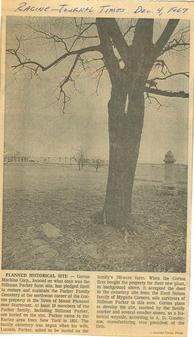

A Dec, 1969 article notes that the site was originally homesteaded by Stillman

Parker who came to the Racine area from New York in 1831.

Oct, 1967 - A (probably) Racine Journal Times article briefly discusses

financial state of the company based upon a talk given by Arthur Pierce,

advertising and sales promotion manager to the local Rotary club. In 1966,

the company had $8.4 Million in sales, aiming for $10 Million in 1967, and to

attain $20 Million within 4-5 years. The company had a 1966 profit of $414,000.

Overseas sales accounted for 4% of sales; 92% of the sales came from outside

of Wisconsin. He commented on the goal of becoming "the nation's predominant

manufacturer of medium-sized tracer and numerically controlled milling machines"

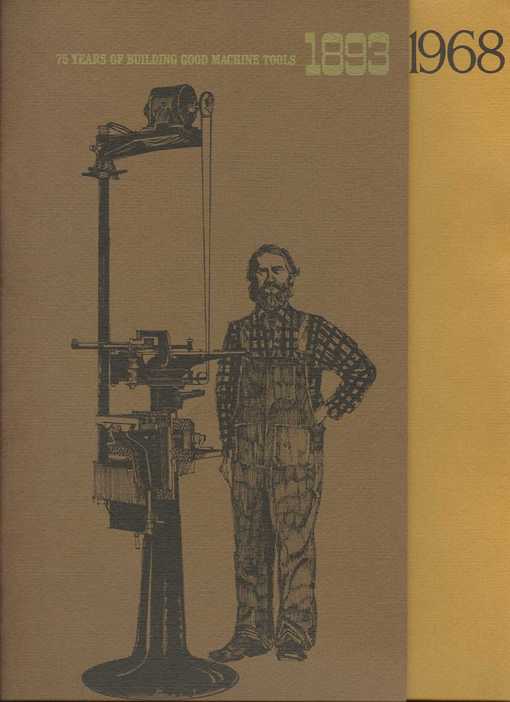

Corporate 75th anniversary

A 75th anniversary booklet

and open_house guide from 1968.

A couple of different invitations were sent out: A version sent to members

of the "Gorton Family"

(presumably staff and their family), and a version sent to a

broader audience. Various photos of

this event also exist

March, 1969 - The company introduces the model 3-48 Tape-Master, a 3-axis NC

(Numerically Controlled) machining center. From photos, it appears to be

a very large mill, roughly 9 feet tall, with a work table about 3 feet by 8 feet.

April, 1969 - A P2-3 makes an appearance in the "Steve Roper" comic strip.

Strange, but true...

March, 1969 - The company introduces the model 3-48 Tape-Master, a 3-axis NC

(Numerically Controlled) machining center. From photos, it appears to be

a very large mill, roughly 9 feet tall, with a work table about 3 feet by 8 feet.

April, 1969 - A P2-3 makes an appearance in the "Steve Roper" comic strip.

Strange, but true...

May - June 1970: the Cleereman Machine operations of Kearney & Trecker are

transferred from Green Bay, WI to the Gorton division of K & T in Racine.

After the transfer, the facility on Highway 11 will employ about 375 people.

The newspaper article this is derived from indicates that machine tool industry

sales have lagged since mid-1969. The Cleereman line is focused on verical

drilling, tapping, boring, and machining.

April 26, 1971 - A Racine Journal Times article indicates that the plant will

close for two weeks and resume 10 May, 1971. This will idle 180 plant workers

and 100 office personnel. The cause is a severe depression in the machine tool

industry.

March 14, 1972: At age 70, George Gorton III retires from Kearney & Trecker.

It is the first time since the company was founded in 1893 that no family

member is employed by the company.

1974: The Gorton Machine division of Kearney & Trecker is closed

May - June 1970: the Cleereman Machine operations of Kearney & Trecker are

transferred from Green Bay, WI to the Gorton division of K & T in Racine.

After the transfer, the facility on Highway 11 will employ about 375 people.

The newspaper article this is derived from indicates that machine tool industry

sales have lagged since mid-1969. The Cleereman line is focused on verical

drilling, tapping, boring, and machining.

April 26, 1971 - A Racine Journal Times article indicates that the plant will

close for two weeks and resume 10 May, 1971. This will idle 180 plant workers

and 100 office personnel. The cause is a severe depression in the machine tool

industry.

March 14, 1972: At age 70, George Gorton III retires from Kearney & Trecker.

It is the first time since the company was founded in 1893 that no family

member is employed by the company.

1974: The Gorton Machine division of Kearney & Trecker is closed

One newspaper article (citing Russell Hedden, K&T's president and CEO)

indicated that by 1972, the Gorton division was losing about $2Million annually.

197x-198x: Kearney & Trecker subsequently becomes Cross & Trecker.

At some point, I believe Cross & Trecker went bankrupt, with the

Patents being assigned to Citicorp. Eventually, Cross & Trecker

is then purchased by Giddings & Lewis in 1991, which in turn is

acquired by TheissenKrupp in 1997.

November, 1974: Art Pierce, former Gorton Sales manager (and then manager

of promotional services at K&T) donates a copy of GGII's unpublished

autobiography, along with multiple scrapbooks of company advertisements from

1911 thru 1970 to the UW Parkside Area Research Center. Note: this particular

copy of GGII's autobiography seems to have updates to the copies held by family.

late 1974 - early 1975: Lars Machine founded by Charles A. Larsen,

formerly a VP of engineering at Gorton.

Lars buys the rights to, and manufactures Gorton products:

cutter-grinders, a small mill (0-16), and the Gorton pantographs.

197x-198x: Kearney & Trecker subsequently becomes Cross & Trecker.

At some point, I believe Cross & Trecker went bankrupt, with the

Patents being assigned to Citicorp. Eventually, Cross & Trecker

is then purchased by Giddings & Lewis in 1991, which in turn is

acquired by TheissenKrupp in 1997.

November, 1974: Art Pierce, former Gorton Sales manager (and then manager

of promotional services at K&T) donates a copy of GGII's unpublished

autobiography, along with multiple scrapbooks of company advertisements from

1911 thru 1970 to the UW Parkside Area Research Center. Note: this particular

copy of GGII's autobiography seems to have updates to the copies held by family.

late 1974 - early 1975: Lars Machine founded by Charles A. Larsen,

formerly a VP of engineering at Gorton.

Lars buys the rights to, and manufactures Gorton products:

cutter-grinders, a small mill (0-16), and the Gorton pantographs.

Raw photo images appearing on

this (and other) pages.

Copyright, 2004 - 2015 Richard Gorton - rcgorton@verizon.net

Please contact me if you wish to use images or content herein

Attendees include (then) Gov. Warren Knowles, George Gorton III, and Francis

Trecker. The 62-acre site will house an initial 135,000 sq. ft factory, with an

accompanying office building to be erected later.

The Racine Journal Times article has some interesting content: The new facility

will enable the company to build three new, significantly larger, machine tools,

and that these new tools are expected to add $5 to $8 Million in annual production

volume.

Attendees include (then) Gov. Warren Knowles, George Gorton III, and Francis

Trecker. The 62-acre site will house an initial 135,000 sq. ft factory, with an

accompanying office building to be erected later.

The Racine Journal Times article has some interesting content: The new facility

will enable the company to build three new, significantly larger, machine tools,

and that these new tools are expected to add $5 to $8 Million in annual production

volume.